Questions? We're Here to Help.

Manufacturing Engineer Courses

Developed for Engineers New to Electronics Manufacturing

Learn the Fundamentals of Electronics Assembly

Introductory to Advanced Courses

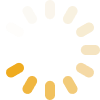

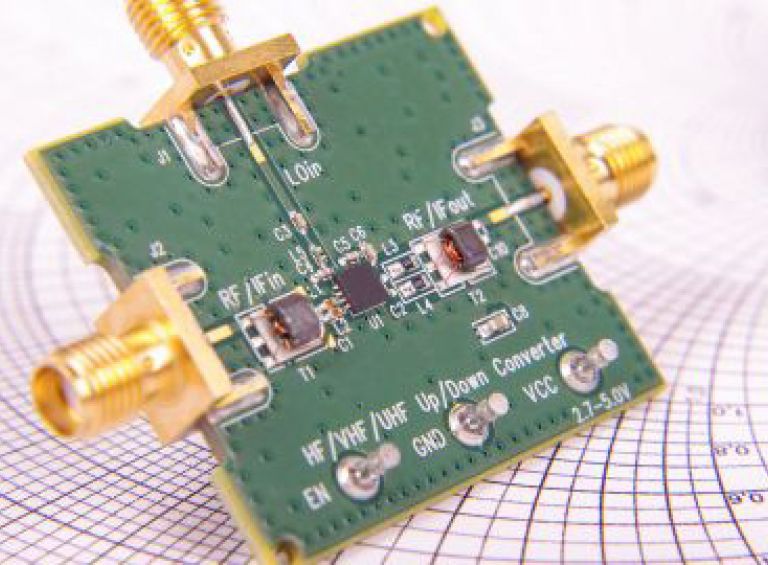

PCB Design

PCB Fabrication and Program Management

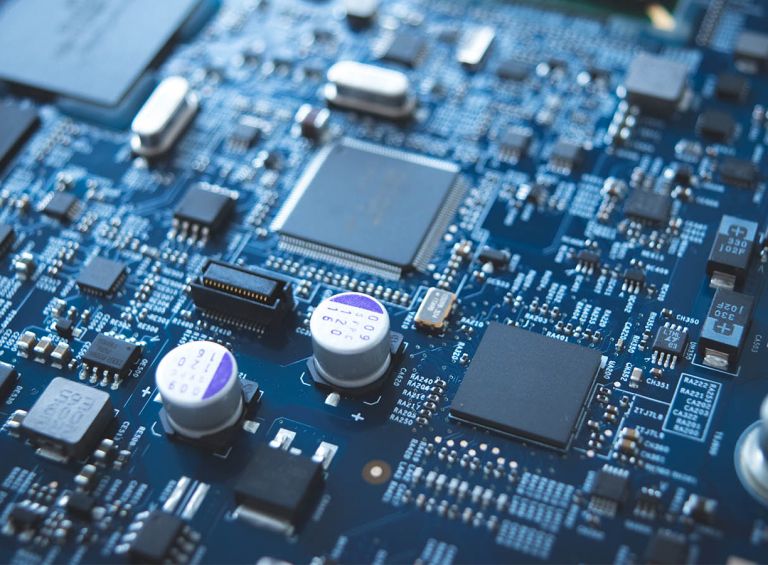

In the competitive printed circuit board fabrication industry, high reliability and high yields are crucial for profitability. That's why process and manufacturing engineers involved in fabrication, assembly, and procurement need to have the necessary knowledge and skills to produce and evaluate top-quality printed circuit boards. This includes understanding materials, chemical processes, equipment parameters, and their impact on board quality.

After completing this course, you will be able to:

Identify and correct control processes that negatively affect circuit board quality

Establish the root cause of potential defects to minimize and prevent loss of quality

Recognize the interrelationships of PCB materials, processes, and equipment and how these relationships affect PCB and PCA quality

Identify the root cause and corrective action for PCB defects, such as interconnect separation, delamination, wedge voids, plating folds, microvoids, surface pitting, and hole wall pull-away

Identify the root cause and corrective action for electrodeposition defects, such as mouse bites, pitting, and domed or crown plating

Identify the root cause and corrective action for solderability and assembly-related issues, such as outgassing, black pad, creep corrosion, and blow holes