Questions?

Capacitación en Fabricación y Montaje Para Ingenieros

Onboarding manufacturing engineers new to the electronics industry can be a daunting task. What if you had a self-paced course that provides a comprehensive overview of the roles and responsibilities of manufacturing engineers in our industry? IPC worked with industry subject-matter experts and instructional designers to create an introductory course that takes approximately 3-1/2 hours to complete. In addition to understanding the role, participants will also learn to use documentation control systems, product identification, and product traceability.

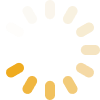

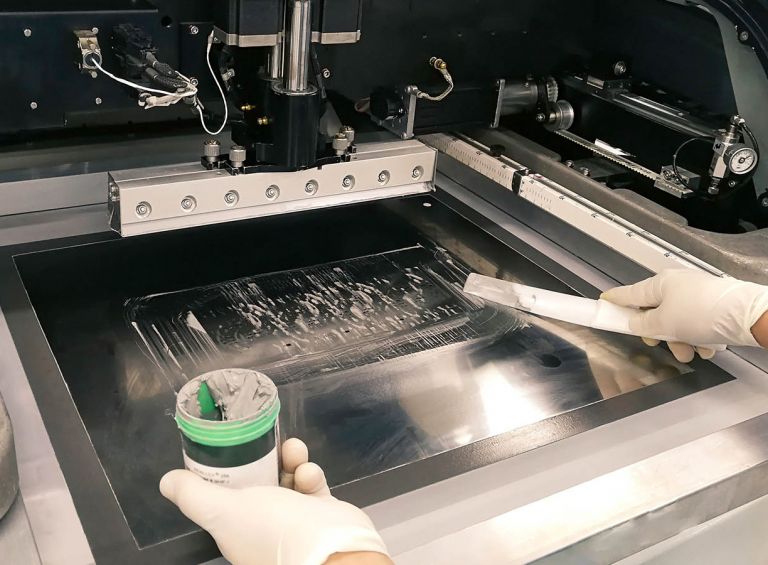

A comprehensive overview of the stencil printing process for a manufacturing engineer. Participants will learn how to select and store solder pastes & adhesives. They will also learn how to create and maintain stencils, the function of the stencil printer, as well as how to set up the stencil printer for a new product introduction, or NPI, run.

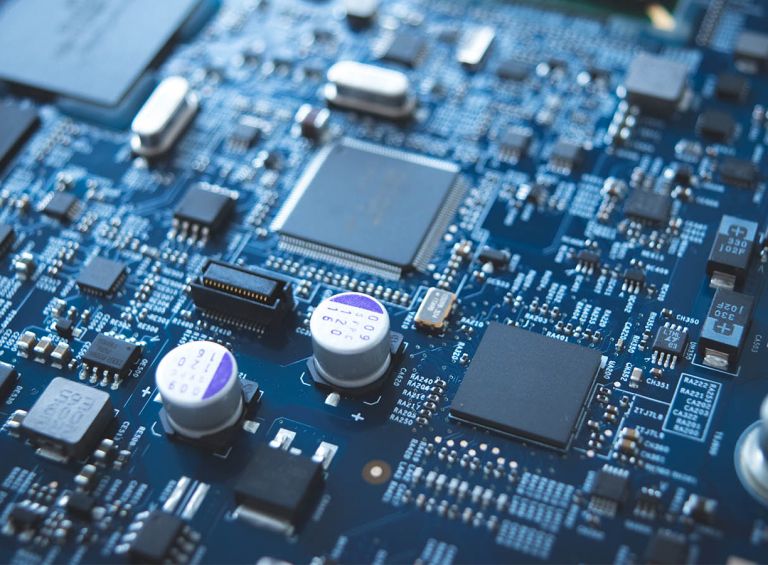

This course provides a comprehensive overview of the surface mount assembly process including information on component considerations, selecting and setting up pick and place machines, and the reflow process. Participants can take this content-specific course to learn more about the role of manufacturing engineers regardless of company size and industry sector.

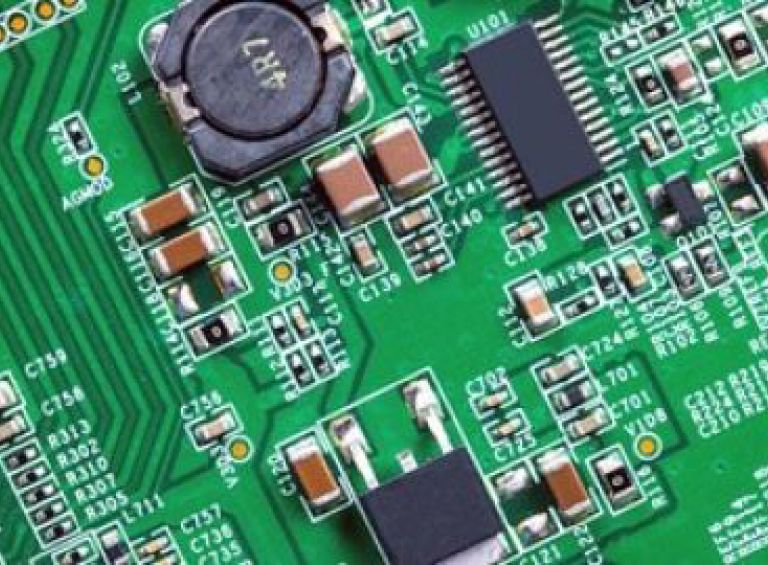

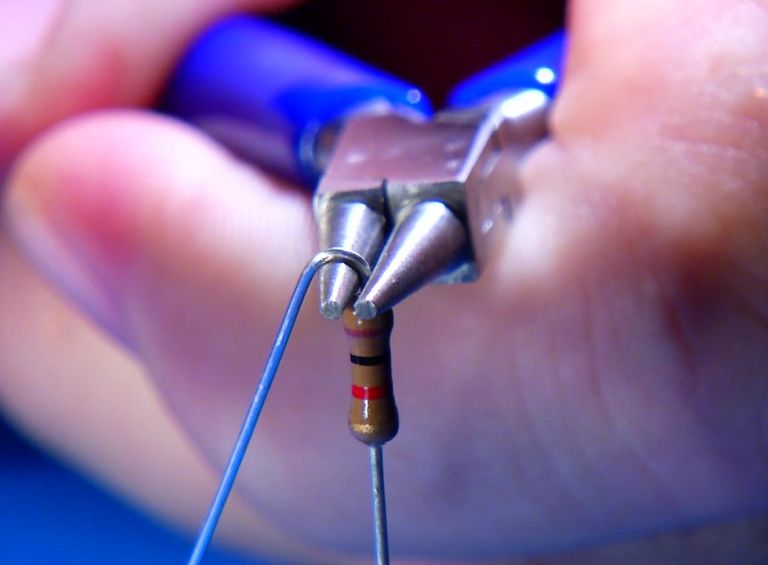

This course provides a comprehensive overview of component preparation, tool selection, manual component insertion, and automated component insertion in electronics assembly with through-hole components. Participants can take this content-specific course to learn more about the role of manufacturing engineers regardless of company size and industry sector.

Capacitación de Montaje Para Operadores e Inspectores

Este curso introduce los riesgos laborales y mejores prácticas de seguridad en el ámbito de la industria electrónica. Después de completar este curso, los participantes podran emplear las herramientas, materiales y procesos claves para garantizar su seguridad y las de sus compañeros de trabajo en una planta de fabricación.

This Inspection of Electronic Assemblies: Introduction course trains participants to perform "incoming inspection" using the essential tools, materials, and processes that deliver consistent quality products. Completion of this course delivers a professional level of proficiency in acceptability standards, inspection methods and tools, documentation, and component characteristics.

Learn how to create industry acceptable solder joints for through-hole and surface mount chip and gull wing components. This innovative multimedia course capitalizes on the power of the hear-see-do methodology to equip students with actionable techniques and best practices they can immediately apply on the job. Students will learn key concepts, tools, and techniques, then use the accompanying practice and project boards, available here, to practice and demonstrate their new skills.

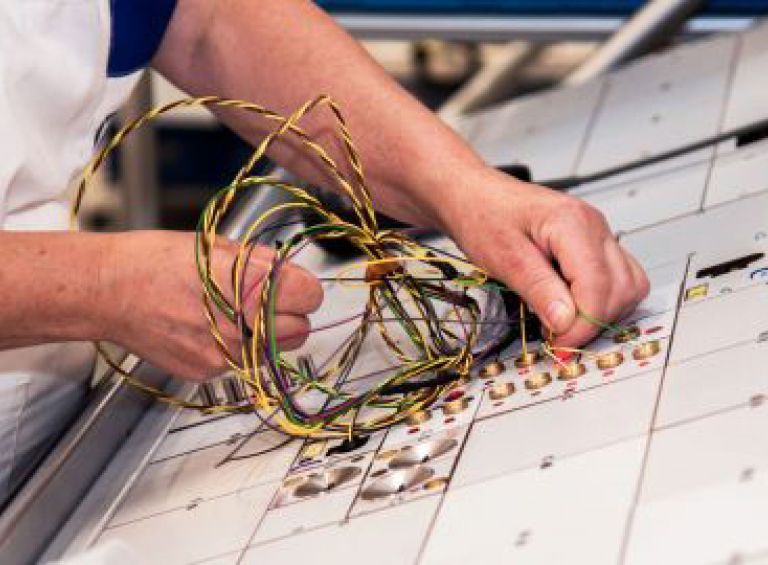

Diseño y Fabricación de PCB

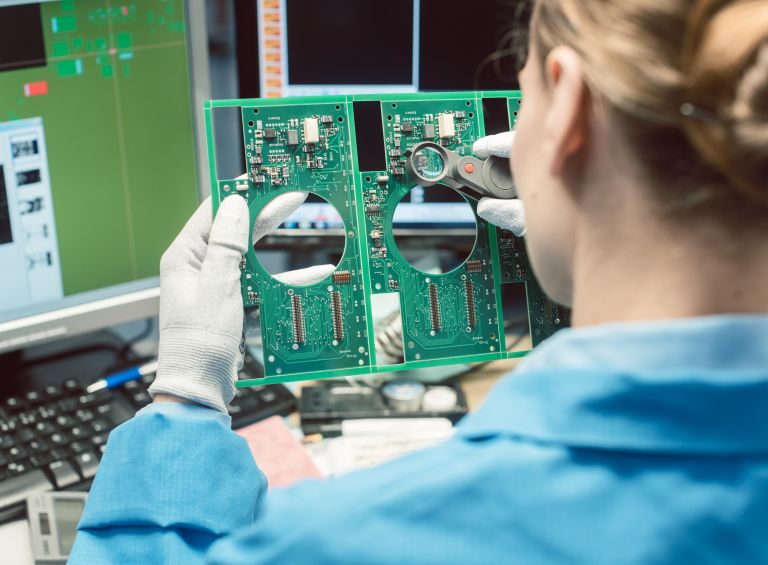

In the competitive printed circuit board fabrication industry, high reliability and high yields are crucial for profitability. That's why process and manufacturing engineers involved in fabrication, assembly, and procurement need to have the necessary knowledge and skills to produce and evaluate top-quality printed circuit boards. This includes understanding materials, chemical processes, equipment parameters, and their impact on board quality.

After completing this course, you will be able to:

Identify and correct control processes that negatively affect circuit board quality

Establish the root cause of potential defects to minimize and prevent loss of quality

Recognize the interrelationships of PCB materials, processes, and equipment and how these relationships affect PCB and PCA quality

Identify the root cause and corrective action for PCB defects, such as interconnect separation, delamination, wedge voids, plating folds, microvoids, surface pitting, and hole wall pull-away

Identify the root cause and corrective action for electrodeposition defects, such as mouse bites, pitting, and domed or crown plating

Identify the root cause and corrective action for solderability and assembly-related issues, such as outgassing, black pad, creep corrosion, and blow holes