Education exam and course content will be unavailable on Saturday, May 10th, from 7:00 PM to 12:00 PM CT as we perform required maintenance.

Result

Help your team enhance product reliability, reduce rework and scrap, and ensure customer satisfaction. This comprehensive overview of process control methodology will empower technicians and engineers to utilize the IPC-A-610 Standard and its associated Handbook to consistently meet acceptance criteria throughout the assembly process.

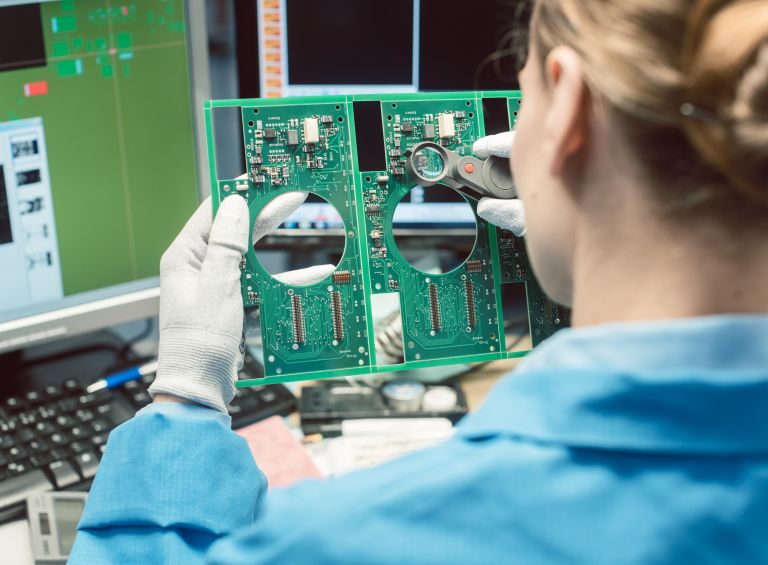

This Inspection of Electronic Assemblies: Introduction course trains participants to perform "incoming inspection" using the essential tools, materials, and processes that deliver consistent quality products. Completion of this course delivers a professional level of proficiency in acceptability standards, inspection methods and tools, documentation, and component characteristics.

Onboarding manufacturing engineers new to the electronics industry can be a daunting task. What if you had a self-paced course that provides a comprehensive overview of the roles and responsibilities of manufacturing engineers in our industry? IPC worked with industry subject-matter experts and instructional designers to create an introductory course that takes approximately 3-1/2 hours to complete. In addition to understanding the role, participants will also learn to use documentation control systems, product identification, and product traceability.

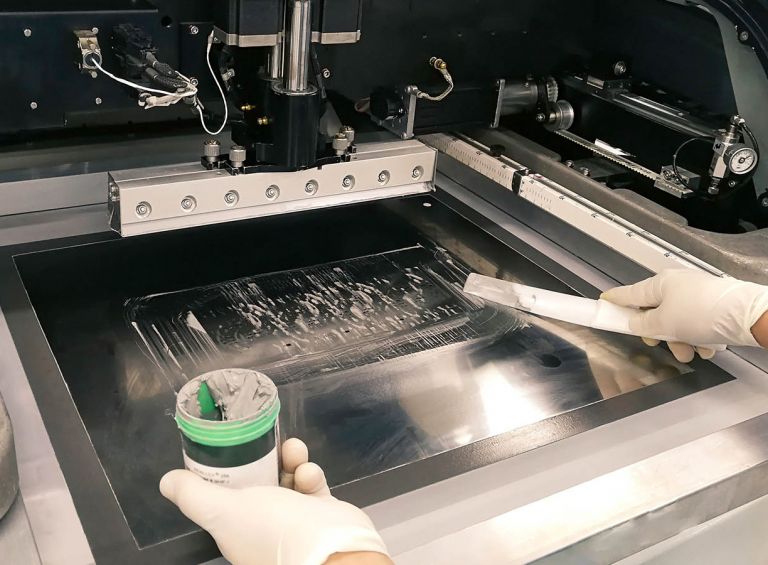

A comprehensive overview of the stencil printing process for a manufacturing engineer. Participants will learn how to select and store solder pastes & adhesives. They will also learn how to create and maintain stencils, the function of the stencil printer, as well as how to set up the stencil printer for a new product introduction, or NPI, run.

This course provides a comprehensive overview of the surface mount assembly process including information on component considerations, selecting and setting up pick and place machines, and the reflow process. Participants can take this content-specific course to learn more about the role of manufacturing engineers regardless of company size and industry sector.

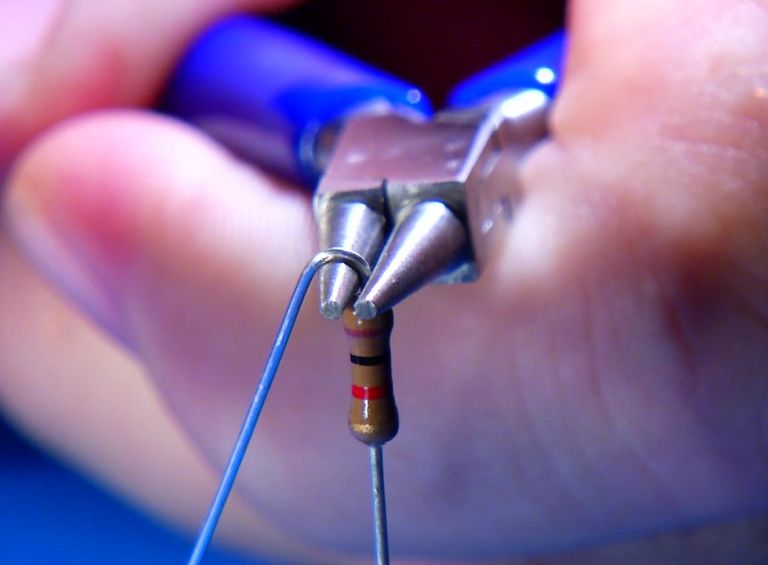

This course provides a comprehensive overview of component preparation, tool selection, manual component insertion, and automated component insertion in electronics assembly with through-hole components. Participants can take this content-specific course to learn more about the role of manufacturing engineers regardless of company size and industry sector.

Learn how to create industry acceptable solder joints for through-hole and surface mount chip and gull wing components. This innovative multimedia course capitalizes on the power of the hear-see-do methodology to equip students with actionable techniques and best practices they can immediately apply on the job. Students will learn key concepts, tools, and techniques, then use the accompanying practice and project boards, available here, to practice and demonstrate their new skills.