Education exam and course content will be unavailable on Saturday, May 10th, from 7:00 PM to 12:00 PM CT as we perform required maintenance.

Result

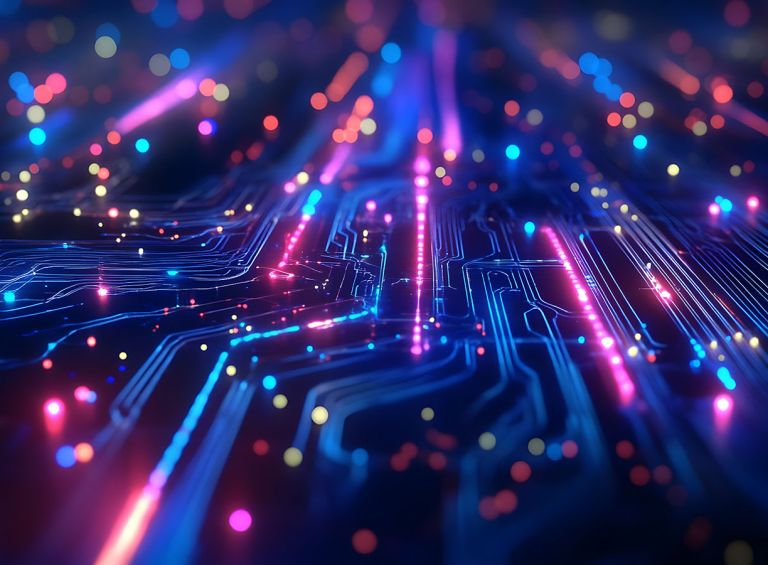

The course will start with design of HDI and advanced packaging concepts. This will be followed by embedded component design and the students will see how concepts from HDI are used in the implementation of embedded components. Next, concepts necessary for the design of wearable electronics and how the use of concepts from HDI and Embedded are necessary to achieve the small size and light weight of wearable electronics.

This course addresses specific design challenges encountered in military and aerospace applications, including the effects of vibration, shock, radiation, and altitude, extended operating temperature range, and other design considerations for high reliability applications. PCB Design for Military & Aerospace Applications also focuses on the impact of these designs on manufacturing and assembly techniques, documentation, and manufacturing file generation.

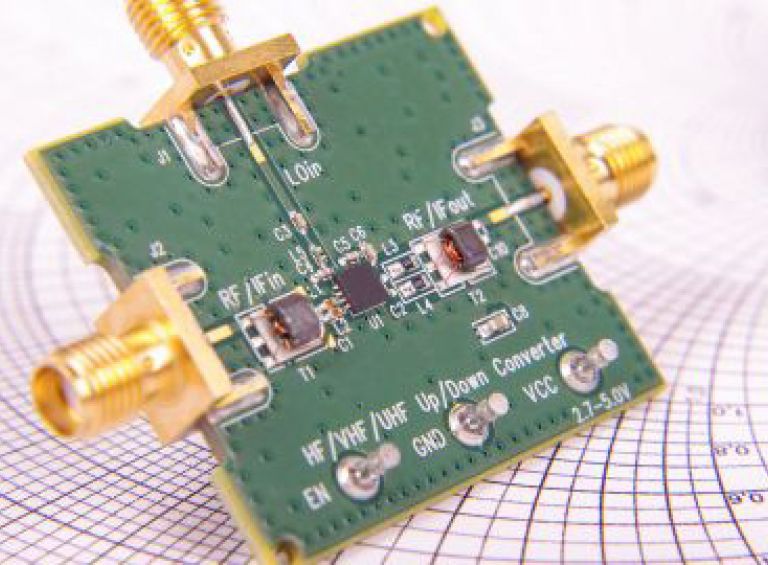

This course provides the theoretical knowledge and practical skills required to create IPC-compliant PCB designs for high-speed analog, radio (RF), and microwave frequencies. This program is designed to provide circuit board designers with a balanced foundation of theoretical knowledge and practical skills in printed circuit board design. Upon completion, participants will be able to:

Design boards for high-speed analog and RF/microwave frequencies.

Understand the trade-offs in materials used in these applications.

Define a board stackup that implements structures that will meet the needs of these designs.

Understand and mitigate signal integrity issues for these designs.

Understand and define the effects of mechanical retention needs for these applications.

Define and implement the tighter manufacturing tolerances needed for these designs.

Understand the use of mixed material stackups in these designs.

Understand the documentation requirements for these designs.

This course is designed to provide the skills necessary to effectively implement designs requiring flex and rigid-flex circuits in accordance with product requirements. PCB Design for Flex & Rigid-Flex Boards also focuses on the impact of these designs on manufacturing and assembly techniques, documentation, and manufacturing file generation.

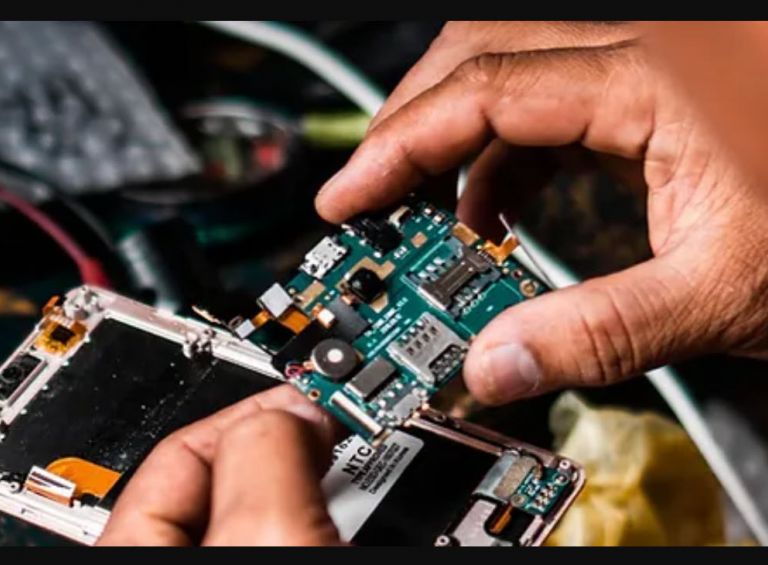

In the competitive printed circuit board fabrication industry, high reliability and high yields are crucial for profitability. That's why process and manufacturing engineers involved in fabrication, assembly, and procurement need to have the necessary knowledge and skills to produce and evaluate top-quality printed circuit boards. This includes understanding materials, chemical processes, equipment parameters, and their impact on board quality.

After completing this course, you will be able to:

Identify and correct control processes that negatively affect circuit board quality

Establish the root cause of potential defects to minimize and prevent loss of quality

Recognize the interrelationships of PCB materials, processes, and equipment and how these relationships affect PCB and PCA quality

Identify the root cause and corrective action for PCB defects, such as interconnect separation, delamination, wedge voids, plating folds, microvoids, surface pitting, and hole wall pull-away

Identify the root cause and corrective action for electrodeposition defects, such as mouse bites, pitting, and domed or crown plating

Identify the root cause and corrective action for solderability and assembly-related issues, such as outgassing, black pad, creep corrosion, and blow holes