Education exam and course content will be unavailable on Saturday, May 10th, from 7:00 PM to 12:00 PM CT as we perform required maintenance.

Result

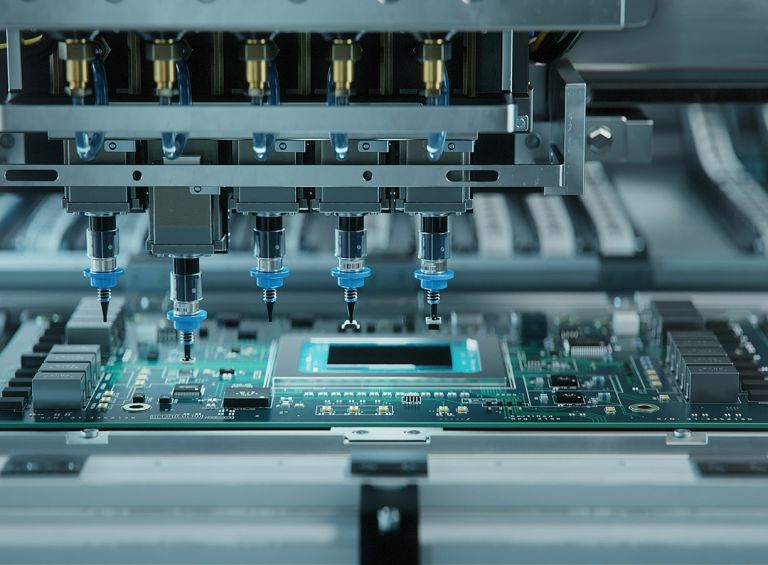

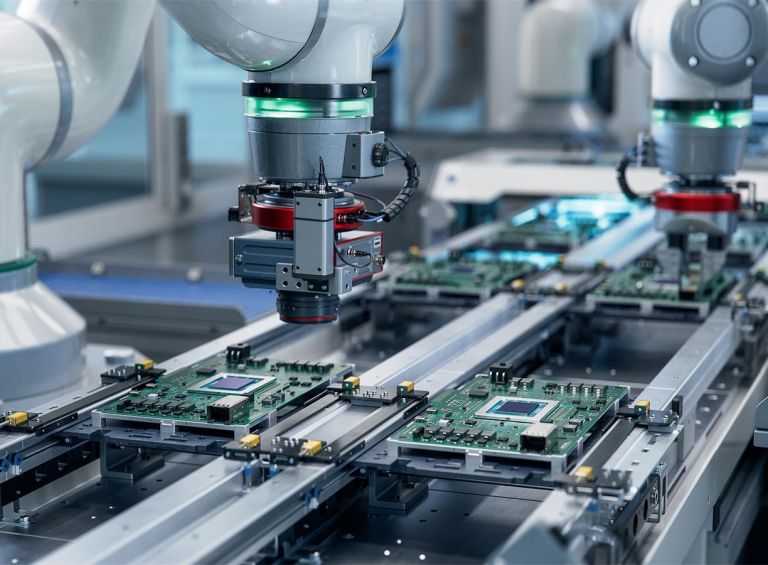

In this course, we will review the data produced by factory machines such as SMT and test equipment and how AI tools can be leveraged to assist with the analysis and interpretation of the data. The course is designed around practical, interactive learning experiences with an anonymized real-world dataset and freely available analysis and visualization tools. AI agents and copilots will be directly created live in the course using UI tools to visually illustrate the concepts and show what is possible with current technologies.

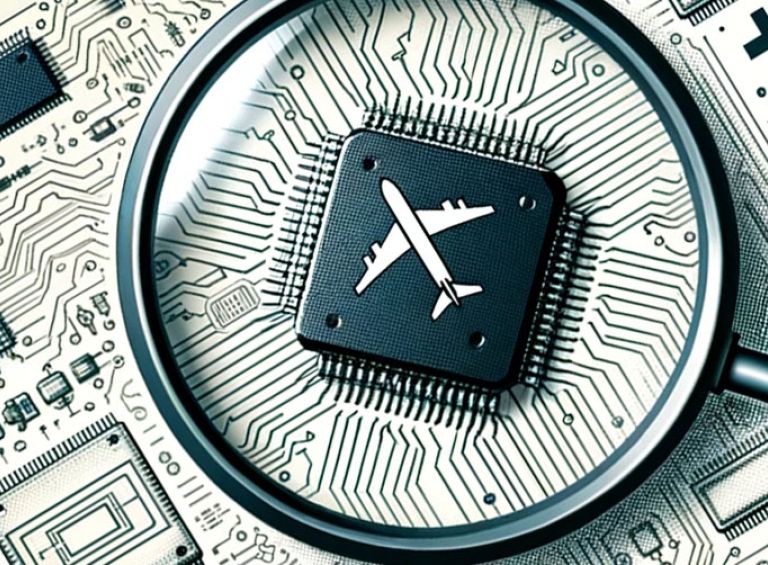

In industries where precision and reliability are non-negotiable, from healthcare to automotive, aerospace, and beyond, the presence of counterfeit electronic components can spell disaster. Not only do these components have the potential to cause significant financial loss, but they also pose serious risks to safety and could be life-threatening.

Help your team enhance product reliability, reduce rework and scrap, and ensure customer satisfaction. This comprehensive overview of process control methodology will empower technicians and engineers to utilize the IPC-A-610 Standard and its associated Handbook to consistently meet acceptance criteria throughout the assembly process.

This course introduces participants to the causes of ESD and the steps you can take to mitigate its effects when handling, storing or transporting ESD-sensitive components in a manufacturing facility. These preventive measures and their application are based on ANSI/ESD S20.20 and other relevant standards.

Stellen Sie den Teilnehmern die Ursachen von ESD und die Maßnahmen vor, die Sie ergreifen können, um ihre Auswirkungen bei der Handhabung, Lagerung oder dem Transport von ESD-empfindlichen Komponenten in einer Produktionsstätte zu mindern. Diese vorbeugenden Maßnahmen und ihre Anwendung basieren auf ANSI/ESD S20.20 und anderen relevanten Standards.

This course introduces participants to the causes of Foreign Object Debris (FOD) and the steps you can take to mitigate its effects when handling, storing, or transporting items in a manufacturing facility. After completing this course, you will be able to employ the key tools, materials, and processes designed to prevent and control the effects of FOD within a manufacturing facility.

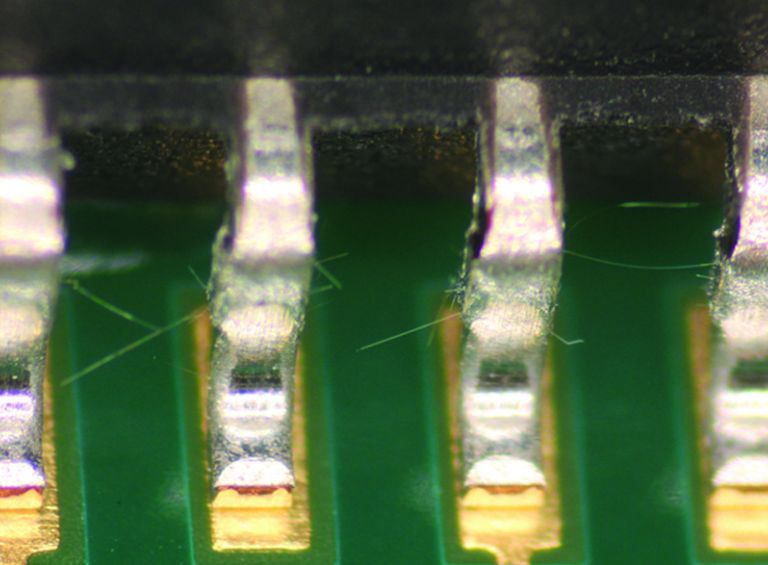

This course provides a holistic coverage on relevant aspects of tin whiskers, including both physical and phenomenal occurrences, as well as fundamental scientific perspectives. We’ll explore various measures to mitigate tin whiskers, as well as their relative effectiveness, and encourage you to join us in questioning and discussing ideas for future solutions.

Ce cours présente aux participants les pratiques de sécurité et les risques professionnels les plus courants dans la fabrication de produits électroniques. Après avoir terminé ce cours, les participants seront en mesure d'utiliser les principaux outils, matériaux et processus conçus pour assurer votre sécurité et celle de vos collègues dans une usine de fabrication.

Dieser Kurs macht die Teilnehmer mit den häufigsten Sicherheitspraktiken und Gefahren am Arbeitsplatz in der Elektronikfertigung vertraut. Nach Abschluss dieses Kurses sind Sie in der Lage, die wichtigsten Instrumente, Materialien und Verfahren, die für Ihre eigene Sicherheit und die Ihrer Mitarbeiter in einer Produktionsanlage vorgesehen sind, einzusetzen.

Discover practical solutions to common manufacturing challenges in the SMT process. Taught by Dr. Jennie Hwang, a globally recognized leader in electronics manufacturing and reliability, this course delves into the root causes of solder joint and assembly defects and provides actionable strategies to prevent them. Ideal for professionals seeking to enhance yield, reduce costs, and ensure product reliability, Module 1 equips participants with real-world insights and engineering principles to tackle production floor issues effectively.

Equip your team to quickly and effectively identify, analyze, and address PCBA production defects. Jim Hall and Phil Zarrow, the authors of Troubleshooting for Electronics Manufacturing and the acclaimed BoardTalk podcast, offer decades of practical insights that students can immediately use to increase reliability, yields, and cost savings.