Preguntas

¿Necesita saber más? Envíanos tus preguntas y te daremos una respuesta.

¿Necesita saber más? Envíanos tus preguntas y te daremos una respuesta.

All virtual class sessions are recorded for review.

WEEK 1 – SESSION 1

Provides an overview of the program: defining, identifying, and analyzing the root cause of defects. It establishes the methodology of troubleshooting which will be presented in detail in subsequent sessions.

Topics include:

WEEK 1 – SESSION 2

Presents, in detail, process relationships which contribute to the formation of defects.

Topics include:

WEEK 2 – SESSION 1

Completes the detailed presentation of process relationships and presents an in-depth example of the application of this troubleshooting methodology using the common defect, solder short.

Topics include:

WEEK 2 – SESSION-2

Presents troubleshooting summaries of other common defects using the established methodology. It will explore how to modify current assembly processes to prevent future defects.

Topics include:

This course is designed for engineers, technicians, operators, and other staff members directly involved in the assembly of printed circuit boards (PCBs).

IPC offers different instructional modalities to suit participants with different needs and preferences. This program is only available in the following modality:

Online-instructor-led: Participants go online to meet with an IPC-certified industry expert at a fixed time twice per week for the duration of the course. Class sessions are usually 1.5 to 2 hours. Participants can also access a video recording of each class session on their IPC EDGE course dashboard.

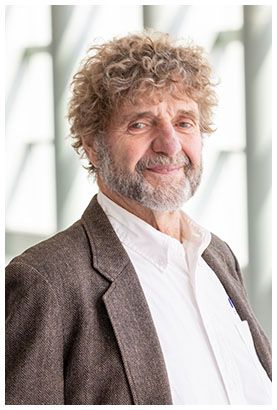

Jim Hall is a principal consultant and Lean Six Sigma Master Black Belt with ITM Consulting. His area of responsibility includes working with OEMs, contract assemblers, and equipment manufacturers to solve design and assembly problems, optimize facility operations, and teach basic and new technologies in private and public forums worldwide.

He has served as the program’s principal instructor, certifying hundreds or engineers in the US, Canada, Mexico, Hong Kong, and China.

As ITM Consulting’s resident Lean Six Sigma Master Black Belt, Jim is a strong proponent of in-process data capture and analysis for all operations.

Mr. Hall, one of the pioneers of reflow technology, has been actively involved in electronic assembly technology for more than 40 years. Jim is co-host of Circuit Insight’s “BoardTalk” audio program.