Education exam and course content will be unavailable on Saturday, May 10th, from 7:00 PM to 12:00 PM CT as we perform required maintenance.

Result

CFX 100 is the first in this 3-part educational series designed to build IPC-CFX expertise. These short, engaging courses provide a comprehensive overview of CFX and machine communication as well as the base requirements for you and your company to get started with CFX. By the end of the series, you will be ready to start sending IPC-CFX messages.

IPC E-Textiles Exchange is a free and open online community for the e-textiles industry to learn, collaborate, and engage. Each month, IPC will post new video presentations and Deeper Dive discussions with subject matter experts from around the world. The community also includes a discussion board for members to interact with others in the IPC E-Textiles Exchange community.

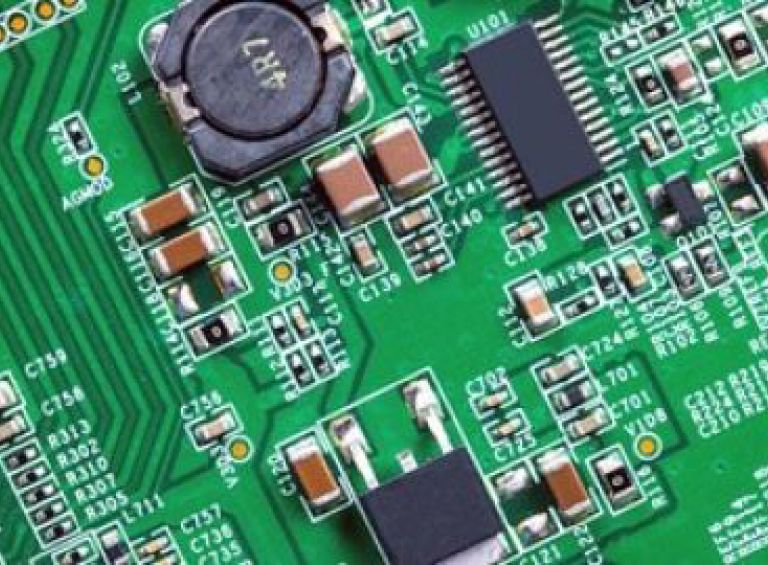

This course introduces participants to the causes of ESD and the steps you can take to mitigate its effects when handling, storing or transporting ESD-sensitive components in a manufacturing facility. These preventive measures and their application are based on ANSI/ESD S20.20 and other relevant standards.

This course introduces participants to the causes of Foreign Object Debris (FOD) and the steps you can take to mitigate its effects when handling, storing, or transporting items in a manufacturing facility. After completing this course, you will be able to employ the key tools, materials, and processes designed to prevent and control the effects of FOD within a manufacturing facility.

Learn how to create industry acceptable solder joints for through-hole and surface mount chip and gull wing components. This innovative multimedia course capitalizes on the power of the hear-see-do methodology to equip students with actionable techniques and best practices they can immediately apply on the job. Students will learn key concepts, tools, and techniques, then use the accompanying practice and project boards, available here, to practice and demonstrate their new skills.